Add vital humidity to your produce storage rooms.

Even the freshest produce is known to deteriorate rather quickly in low humidity conditions. Refrigeration system tends to dry the air in the cold room, as does frequent in and out personnel traffic. Proper humidity level needs to be continuously restored in order to maintain high produce quality.

It is universally accepted that high humidity conditions help significantly in the retention of the natural moisture content in stored produce. Miatech’s humidification systems allow user to set and maintain a steady RH level, thereby cutting weight loss by half or more.

Being a living organism, fresh produce, when properly hydrated is proven to stay healthy longer and have an increased ability to fight harmful microorganisms. Proper humidification ensures extended shelf life.

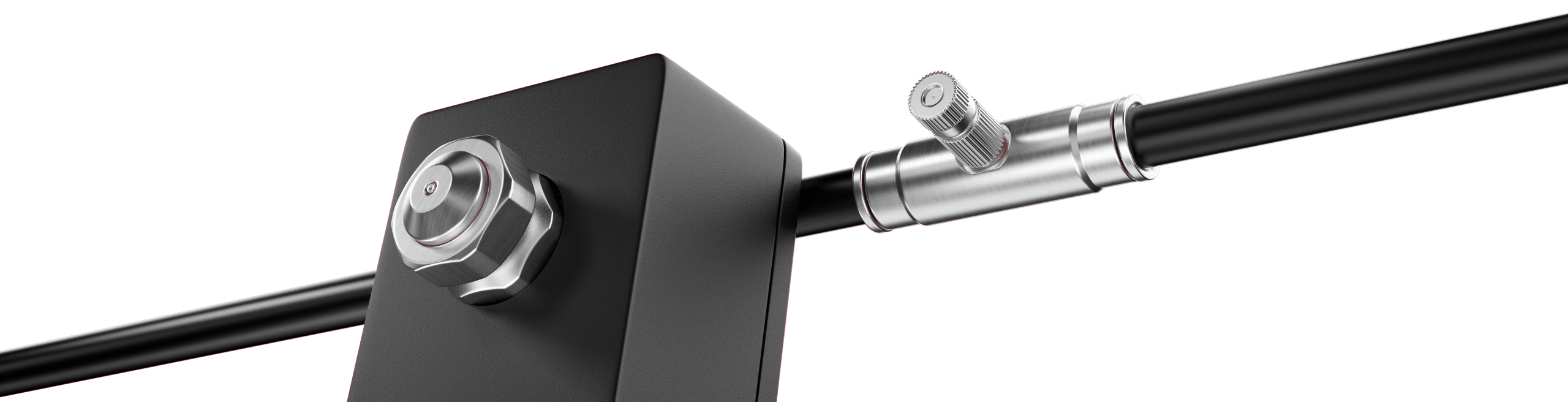

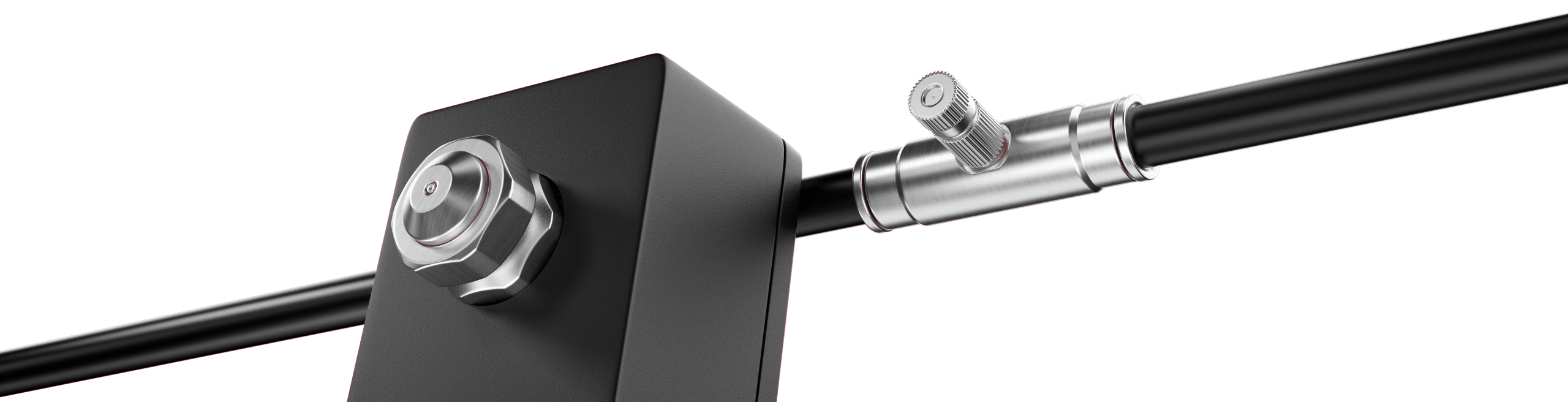

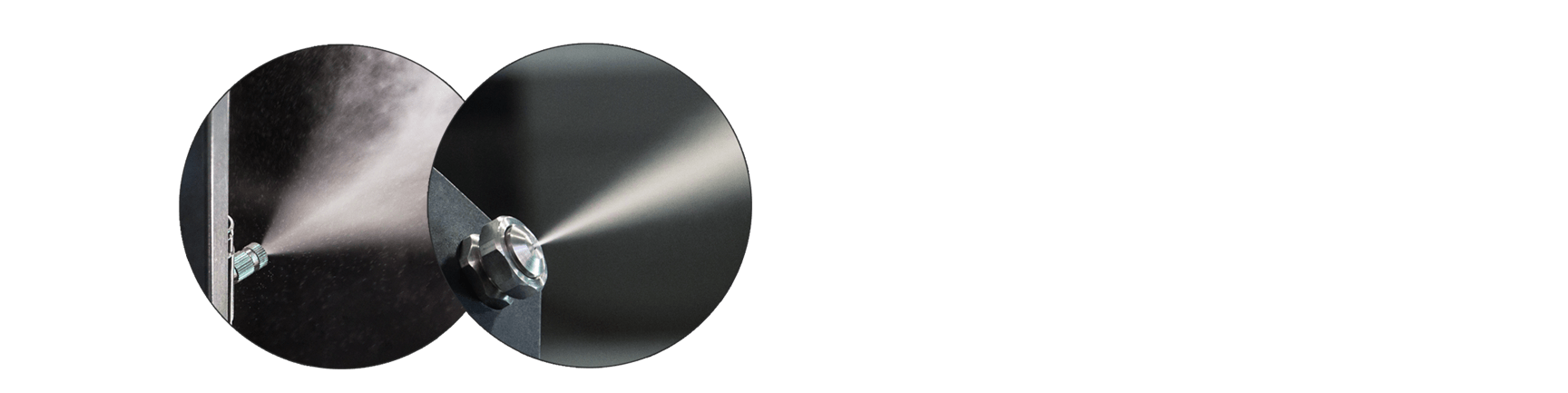

We have designed several types of the fogging heads for maintaining advantageous level of humidity. All of them create ultra-light fog, but the amount of spread moisture varies. The choice depends on the customer demand, as well as on the size and layout of the storage room.

All our humidification systems are controlled by the humidistat, thus desired level of humidity can be easily set up and maintained consistent in a given produce storage area requiring no attention from the personnel.

Our friendly staff will answer any of your questions.

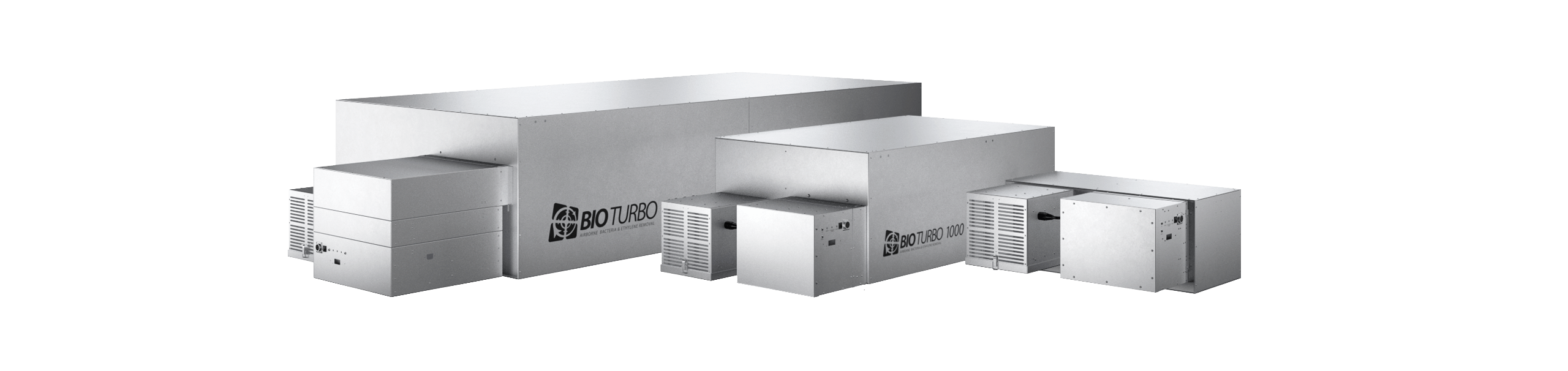

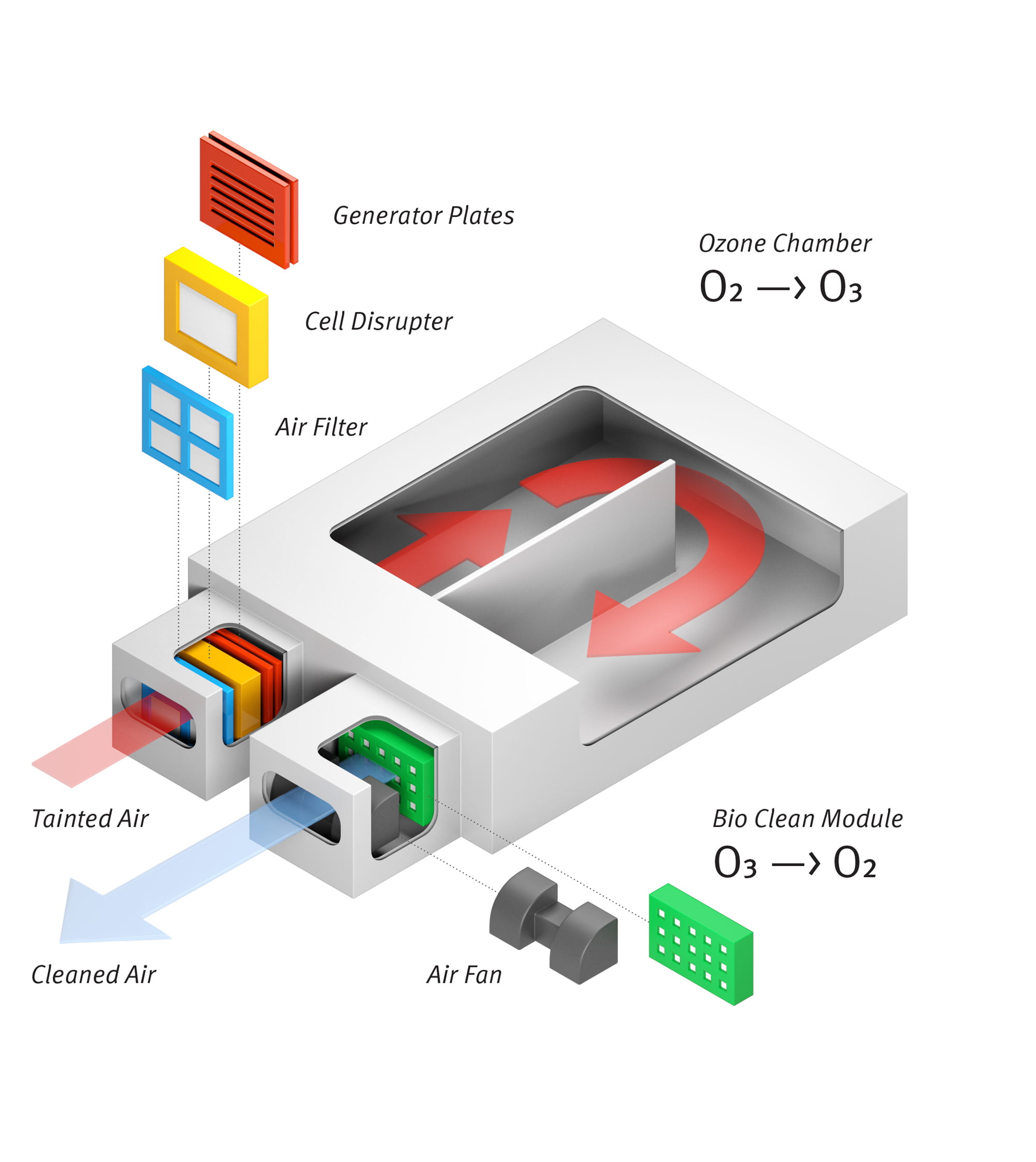

Utilizes the power of ozone in a completely unique and safe way.

Contains a specially designed cell disrupter that kills airborne pathogens.

Cleans air of mold spores, preventing it from spreading.

By removing ethylene from the storage atmosphere, Bio Turbo prevents the process of premature ripening.

By killing airborne bacteria, Bio Turbo prevents cross contamination which often takes place when produce of various types are stored in one cold room.

Our friendly staff will answer any of your questions.